- Get link

- X

- Other Apps

In specialized soundproof drywall the solid gypsum core is replaced with an inner layer of gypsum viscoelastic and ceramics. Made mainly of gypsum calcium sulfate dihydrate it is one of the best materials for soundproof walls.

Building Soundproof Walls Fine Homebuilding

Building Soundproof Walls Fine Homebuilding

As a construction material its useful because its inexpensive easy to use and widely available.

Sound deadening drywall. Soundproof drywall does work and is a very effective noise control solution. The award winning QuietRock and complete line of Quiet accessory products became part of the PABCO Gypsum family in August 2013. The two main types of drywall commonly used in soundproofing are your regular type X drywall and your soundproof drywalls such as QuietRock drywall.

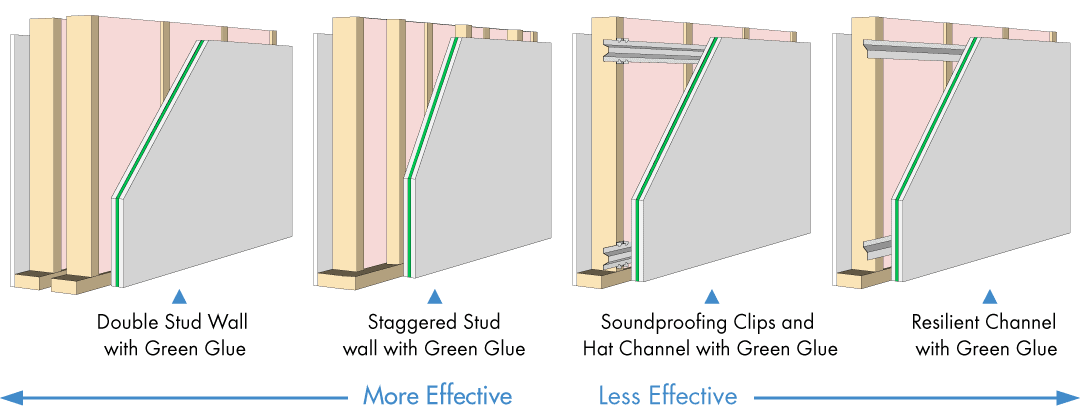

Increasing the density of the wall. Some building experts claim that QuietRock and similar products can produce sound dampening qualities equal to. When it comes to soundproofing a drywall there are three ways of doing that.

Prices can range from 4x to up to 15x the cost of standard 12 or 58 Type X drywall. Before securing the new drywall over the existing drywall apply a layer of Green Glue a noiseproofing compound on top of the wall. Adding insulation to the wall.

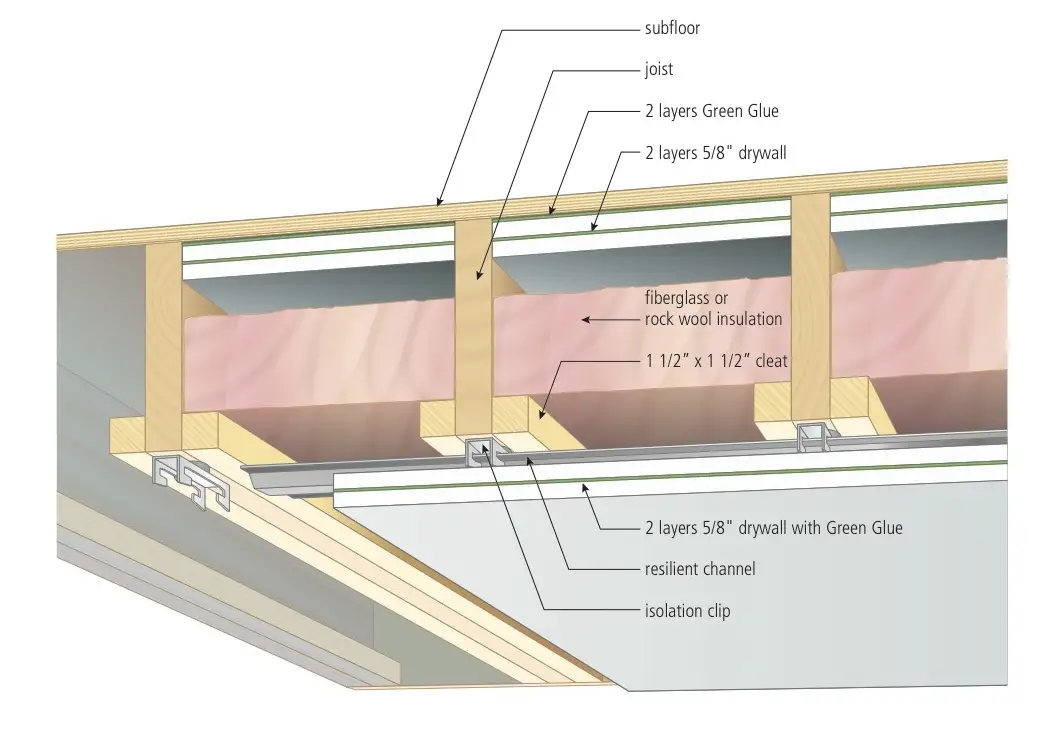

Checking for sound leaks. Most commonly two layers of drywall are used to provide that extra mass that can block sound. One of the most commonly used method of sound dampening involves adding extra insulation to the wall cavity.

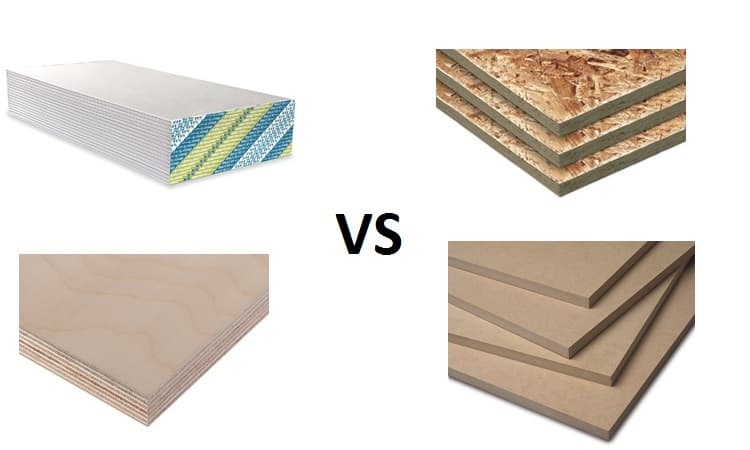

Plywood is the least effective since sound transfers quickly through the wood. OSB and MDF have similar soundproofing characteristics as drywall but they have other drawbacks that make them a less optimal choice in many situations. There are several brands of soundproof drywall available but the best known is QuietRock.

In terms of soundproofing its not great. Soundproof drywalls generally use an inner layer of gypsum viscoelastic and ceramics to up their STC. Successfully soundproofing a wall involves employing one or more of four strategies commonly used by builders.

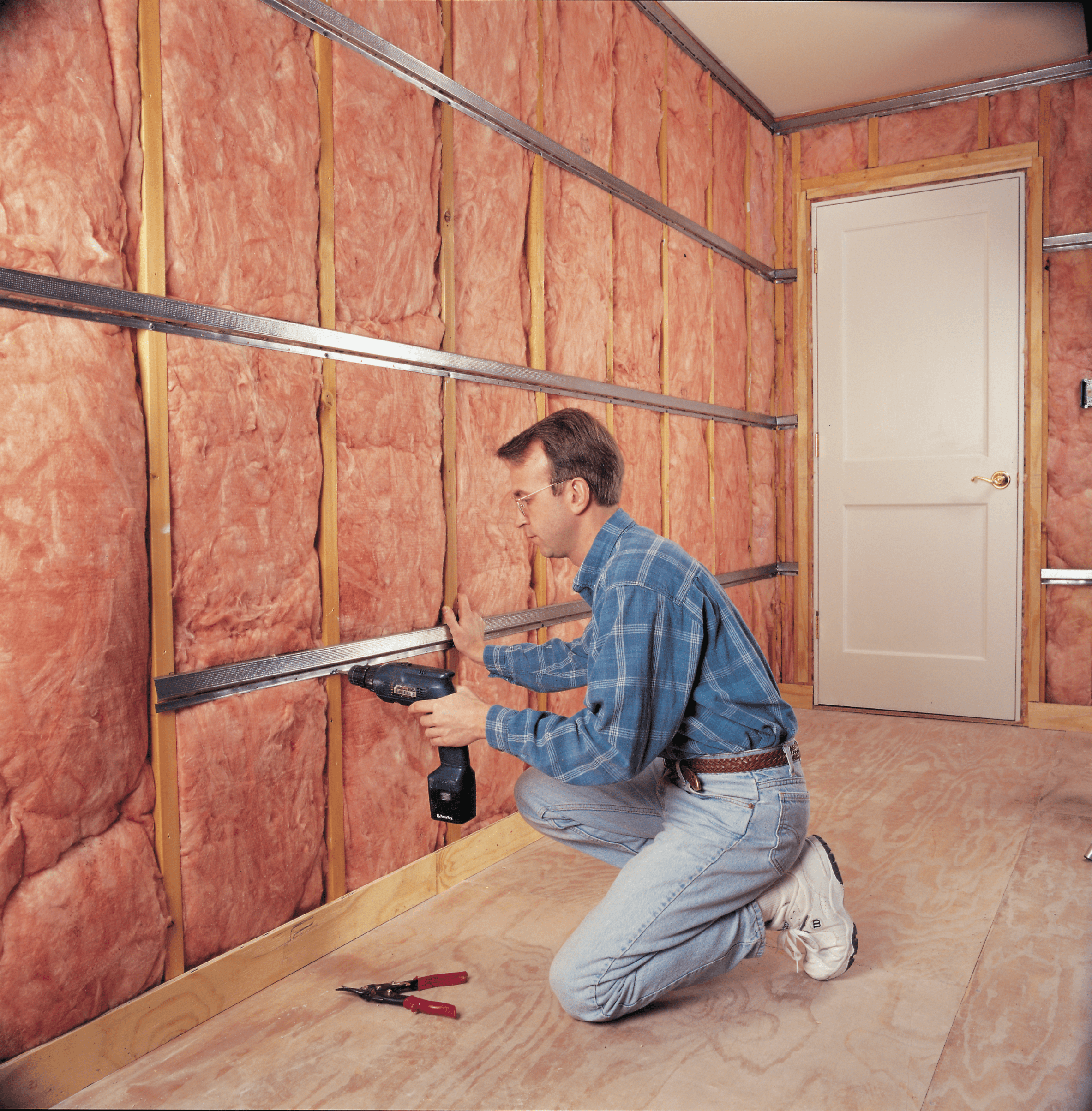

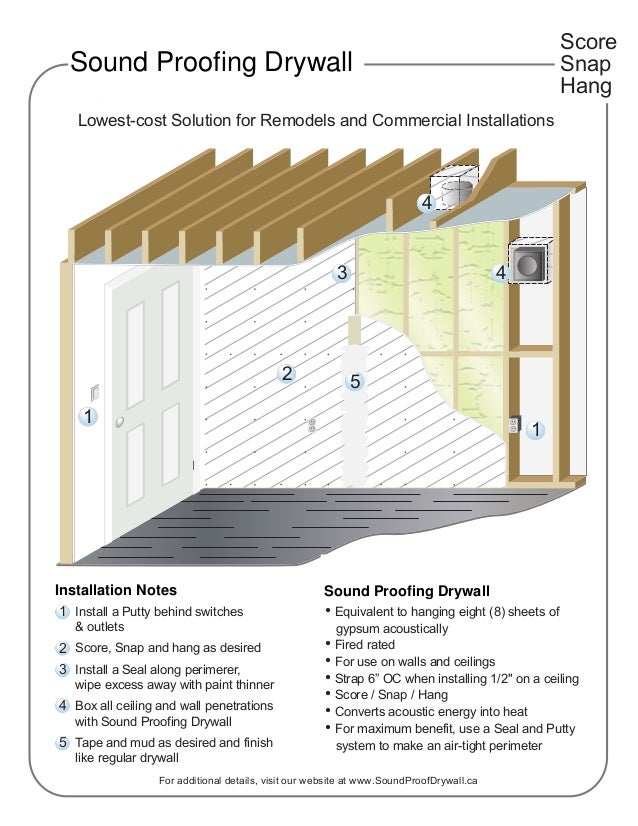

In fact its basically the wall we mentioned above. Acoustic sound sealants benefit drywall ceilings by preventing unwanted sounds from escaping cracks in soundproofing treatments. The first is to decouple the drywall from the studs so that the sound doesnt pass.

Its also compatible with flooring systems wall-penetrating equipment door sills and other exposed and unexposed projects. Sound dampening insulation can be installed between studs before drywall is installed. Higher STC numbers mean better soundproofing.

Because of the ease of implementation and relatively low cost sound dampening insulation is commonly used in almost all forms of construction. Gypsum is the core component to drywall as it is affordable fire-proof and helps dampen noise. Sound-dampening gypsum board is mostly carried by specialized distributors and its recommended to.

Checking for leaks through which sounds might be escaping and blocking them. 545 works well even on low-frequency noise too. The reason why QuietRock is such a popular option for soundproofing is that it is the first sound dampening panel to ever come to market.

Drywall is the most cost-effective and the most noise-reducing since it has the most mass. Sound waves will easily bounce off it and transfer through it. Drywall is made from a sheet of gypsum sandwiched between 2 sheets of paper.

Then position the new drywall over the existing wall and use screws to attach it to the studs and secure it in place. The 1-38 thick 48 sheets are a hefty 200-pounds 625 lbsft². For instance an STC of 50 means that you will not hear a person talking loudly on the other side of a wall.

The other advantage is that its easier to install than some of. These materials work together to create a better barrier to block noise. Other brands include CertainTeeds SilentFX and National Gypsums SoundBreak.

Soundproof drywall also known as soundproof plasterboard or sound dampening gypsum board has an extra layer sandwiched in the middle which is made up of gypsum viscoelastic polymers and ceramic material. Some of the most popular soundproof drywalls are. Steps for Soundproofing a Drywall.

The simplest way is to sandwich another layer of 58 drywall. QuietRock the first and most technically advanced sound reducing drywall was developed in 2003. Here is our list of some of the best drywall you should use when soundproofing a wall i your home or office.

An 11 layered high-performance drywall panel that is recommended for home or commercial studios sound rooms or theaters. As you might imagine sealing sound drafts is great but you need more than that. They have tapered edges and are STC rated between 60 and 80 depending on wall construction.

The steps to take concerning each of these are as follows. Best Drywall For Soundproofing. For this method choose a sound deadening drywall.

How To Soundproof Your Home Theater With Drywall Boomspeaker Com

How To Soundproof Your Home Theater With Drywall Boomspeaker Com

Soundproof Drywall Wallboard Supply Company

Soundproof Drywall Wallboard Supply Company

How To Keep The Noise Down Greenbuildingadvisor

How To Keep The Noise Down Greenbuildingadvisor

Soundproofing A Basement Workshop Technical Details Videos Baileylineroad

Soundproofing A Basement Workshop Technical Details Videos Baileylineroad

Soundproofing How To Soundproof A Room Diy Project The Family Handyman

Soundproofing How To Soundproof A Room Diy Project The Family Handyman

Soundproofing A Wall Acoustical Surfaces

Soundproofing A Wall Acoustical Surfaces

Soundproofing Drywall Installation Diagram

Soundproofing Drywall Installation Diagram

Soundproof Drywall Wallboard Supply Company

Soundproof Drywall Wallboard Supply Company

![]() Should I Use Sound Board To Soundproof My Room Soundproofing Company

Should I Use Sound Board To Soundproof My Room Soundproofing Company

What Are The Four Elements Of Soundproofing

What Are The Four Elements Of Soundproofing

Quietrock Vs Double Drywall Green Glue Which Is Better Soundproofing

Quietrock Vs Double Drywall Green Glue Which Is Better Soundproofing

Soundproof Drywall Wallboard Supply Company

Soundproof Drywall Wallboard Supply Company

Drywall Vs Osb Vs Plywood Vs Mdf For Soundproofing Which Is Better

Drywall Vs Osb Vs Plywood Vs Mdf For Soundproofing Which Is Better

Comments

Post a Comment